Steve Hann from etc boards

Earlier this month the annual Wooden Surfboard Day was held at Currumbin. Tenth time it's been run, and though much of the focus is still around 'the build', the techniques and the craftmanship in each board, some shapers have progressed far beyond the simplicity of the Alaia.

Steve Hann is a Buderim-based shaper who's mixing organic materials with a progressive take on surfing. Rather than being code for heavy and slow, Steve's wooden boards have zip and liveliness. He's also experimenting with materials from the fringe, hoping to make them more acceptable and popular.

Jim Tomkins bailed up Steve just before he made his annual trip down to the Wooden Board Day.

Jim Tomkins: Talk me through the construction of an eco-board.

Steve Hann: It starts with an EPS blank that I hotwire from a solid block. Once the basic blank is cut I handshape the rest of the board with exception of the rails – They get shaped later in cork. From here I fix a 3mm paulownia parabolic stringer then vacuum bag paulownia skins to the top and bottom. Once it’s out of the bag, everything is cleaned up and cork rails are attached. The cork rails are shaped, fin boxes and leash plug added, then the whole board is finished in lanolin. The process can be completed in about two days.

What are the advantages of using paulownia?

Paulownia is the perfect organic building material for a marine environment. It's highly water resistant, mold resistant, and incredibly light yet maintains great tooling and machining characteristics, unlike balsa wood.

As a bonus it's also fire and termite resistant which is great for when storing large stacks of it around the house. I personally think it would make a great building material however a heap of potential growers got burnt in a poorly executed paulownia scheme about twenty years ago which unfortunately makes it harder to source locally today.

And the lanolin finish, how does that work?

Lanolin is a by-product of sheep wool. I use it to saturate the paulownia wood on a finished surfboard. Once it has been applied and is dry - which takes a couple of hours - it provides total protection and waterproofs the paulownia.

As a bonus, boards with a lanolin finish can be surfed wax free as the lanolin gets sticky when in contact with salt water. Reapplication of lanolin is only required every 8-10 surfs and involves just a simple wipe down that takes about two minutes.

A paulownia lanolin board will last for years.

Doesn’t the sticky finish slow the board down?

People ask me that and I have theories that may or may not be right, but what I do know is that it is that the lanolin finish boards feel faster. My theory, similar to that of a glassed boards with a matt finish, is that the water particles stick to the lanolin surface so in fact you have the water particles sliding on the wave not the lanolin which in theory is resulting in less friction.

I was recently listening to a podcast featuring Tom Wegener and he too states that paulownia/lanolin boards are fast.

The Dunny Door model has got some attention lately?

Yeah, I’ve invested quite a few years perfecting that model. It started off as one of my first eco-boards and was basically just a rectangular slab with a quad setup – hence it got the name Dunny Door. It actually surfed amazing, especially in small crappy surf. It was a 5’4” with around 38 litres volume, but I found that the one-size board suited everyone. I had guys weighing from 68kg through to 105kg units riding the same board and all with positive results. It was such a good all round board.

The super wide tail, however, though great for speed, had a few issues with maneuverability. The problem was though that by pulling the tail in you lost some of the speed and the floating, lightness feeling of the original.

The board evolved through quite a few revisions but I was never entirely happy with the setup as a whole. I really needed the speed and feeling of the original yet find a way to get the maneuverability of a performance board in there.

The missing link for me came when Grant Newby lent me a 7’6” mini-mal with a chine rail bottom. I normally don’t surf boards over six foot and at first wasn’t interested but he told me to just take it and try it out. It blew my mind! The speed that board generated with those specific contours were unlike anything else I had ridden.

So I incorporated a similar setup into my 5’4” Dunny Door model and it transformed that board. It gave me the speed and weightlessness of the original plus with the looseness of a twinny setup makes the board lethal for big carves and snaps off the lip. It was the answer I’d spent so long looking for.

Since then I've expanded the range of the Dunny Door to also include a 6’2” and a 7’6”. They are all twin fins and all surf brilliantly. Currently I’m also looking at twinzer setups in the range as well. I do a bunch of other boards and customs but it’s my Dunny Doors that I am most proud of. All of the Dunny Door range comes in glassed epoxy and glass-free eco models.

What exactly is a chine rail and how does it work?

Basically a chine rail is just a bevel on the underside of the board at the rail. It works great on my mini-Simmons and fish-style boards. It does a couple of things. Firstly, it allows me to get more volume into the rail area whilst maintaining a performance rail. I run the chine about 2”- 2½” wide and it takes about ¼” off the rail. Therefore I can build a 2¾” rail that is effectively 2½” without losing the volume and paddle power of a thicker board.

In addition, a chine rail has two hard edges which act as release points. If you think about a normal surfboard rail the water wraps around the curved rail and hugs onto the board. With a chine the water is released and thus results in more speed. They also create exceptional hold in steep faces. I mostly use chines in conjunction with a twin fin setup. Adding chine rails to my retro board range has really been the missing link for me and everyone that has ridden these boards has come back with very positive feedback.

Where do you see ETC boards going in a design sense over the next few years?

I’m loving all the enviro materials that are slowly becoming mainstream. The term enviro seems to put people off, as some people think that using these materials makes for a sub-par board. In fact I'm finding the opposite, and by using these materials, such as paulownia, eco-resins, basalt and flax cloths, we are able to create stronger, longer lasting boards that exhibit better performance characteristics than traditional boards.

I’m really happy with my building process both in eco and glassed boards and I plan to continue refining and building boards that are just fun to surf. I love all the retro and alternate shapes and find there is so much more fun to be had surfing than just riding high performance boards.

The fact is, unless you go to Indo, you’re seldom riding performance waves in Australia so why limit yourself to a performance board?

etcsurfboards.com.au

etc surfboards on Facebook

and on Instagram

Comments

What are they worth? $ I would get one.

Prices on his website Red

Been following Steve's work now for a few years. Very nice boards IMHO.

Yew Steve!! Stoked Swellnet has given him some exposure!! We have worked with Steve over the years with materials and he makes some amazing boards! He also help us design and makes our shaping "signature" tools for us, which we have heaps of customers loving these! All the tools you need in the shaping shed all made from left over wood from his builds, so the eco range just doesn't stop with his boards!

I wonder how they go in something a wee bit heavier than the sunshine coast beachies?

They go great memlasurf. Tested thoroughly in Samoa and Indo. If you go to my insta page (link at bottom of article) there's a pic of one being surfed in Samatra in the recent large swell they had. Cheers

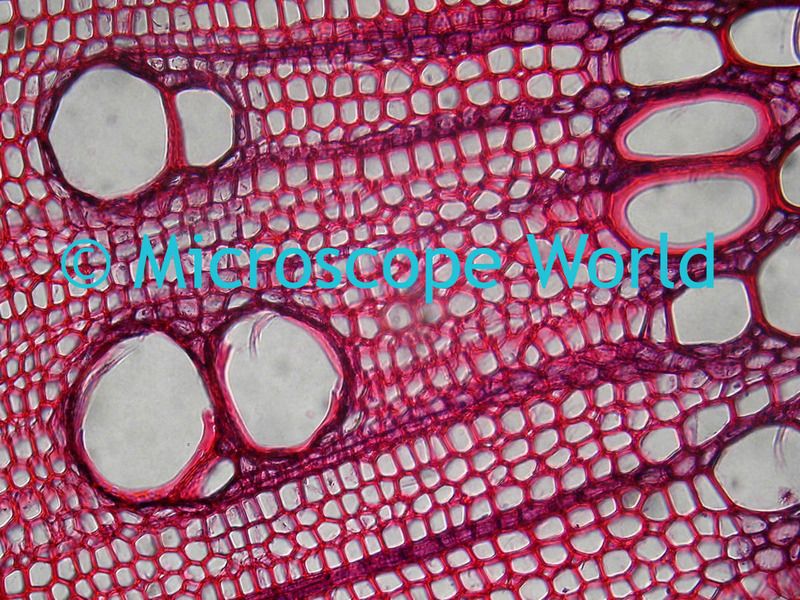

Here is a photo of Paulownia woods structure seen under a microscope.

It is not disimilar to the hydrophobic structure of a butterflys wing.

Great to see boards built with scientific logic, stiff, biodegradable materials ( wood has similar stiffness to carbon fibre) lots of planing area & volume for a given length, no concessions to current fashions! Great work! No wonder they perform so well.

Here is a link to Grant Newbys blog where he takes you through the complete surfboard build process {scroll down a bit}

https://surfboardsbygrantnewby.blogspot.com/search?updated-max=2017-07-1...

An alternative to the lanolin finish and equally as good is orange tung oil.

Several years ago I did an experiment with orange tung oil and paulownia where I applied 3 coats and a week later sanded the wood with a disc sander and the sand paper became clogged up, it was clearly evident that the tung oil had penetrated well into the wood.

thanks ph-surph. great link. great to see there are a bunch of people working in this direction

Oh man, this could be exactly what I've been looking for.

High volume, environmentally friendly pocket rocket for taking off where the MAMOLs* fear to go.

Made a 6'7 pawlonia singlefin with Tree2Sea down in Mornington a few years. I really want to get to a place where my quiver is not made from all the horribly toxic stuff that's the norm.

*Middle Aged Men On Longboards

Pity Steve is using toxic foam core, it's become the fast and favoured construction method.

Lanolin reduces surface tension, water beads and runs off, good for months, gradually builds up a wax finish.

Paulownia is soft, fingernail indents easily, lowest strength group S8 SD8, Youngs modulus 4.38 GPa (carbon fibre 180), susceptible to mould and insect attack, resists salt water, low resin, high silica, course, uneven texture, very large pores. Without resin or glass is fragile, but repairable once the lanolin is stripped. I've stopped using it for structural, it's too weak, good for blocks, fillets.

Bugger. Is that true?

Wonder how a mycelium core would go.

hey btm

>>Pity Steve is using toxic foam core, it's become the fast and favoured construction method.

is there a viable alternative?

also, i've done a little reading around this the last few weeks (but have next to zero knowledge about the whole thing). it seems like most of the blokes making this kind of board are using paulowina, if i understand correctly you're saying it's not the go. again, is there a viable alternative?

thanks

Hi bigtreeman, thanks for joining the discussion. You are correct I do build using a toxic foam core. I do however view it as a viable alternative being fully recyclable. All of my scraps are recycled and nothing is sent to landfill. I would love to use mushroom foam or another greener alternative and if/when they become available and affordable I'll be the first to sign up. You are also correct that paulownia does have its limitations however I have glassless paulownia boards 5/6yrs old and still look and perform as good as when they were first built. Mould is easily preventable by not washing the salt off after surfing and not leaving it wet in a bag. I'm not trying to break any records to build the greenest surfboard, just trying to show others there are options that perform as well as a traditional construction yet are much healthier for the environment, shaper and end user. If you're ever on the Sunshine Coast look me up I'd love to show you around and let you take one for a ride. Cheers, S.

If the aim is to reduce and eventually stop using plastics ? As Steve said he has optional glassed or naked lanolin. Paulownia gets strength from epoxy/glass wrapping. I've been trying different woods, glass, epoxy, glues, hemp, bamboo, etc and different construction techniques for over 8 years now. strength<->weight. I still like paulownia, it just has it's limitations.

cheers. it's good to see there's such an underground movement using alternative materials - hope it becomes mainstream. and hope the shapers into it now can cash in a bit if that happens

IT is happening, but very slowly, here is a video of the recent European wooden surfboard day.

Interesting interview with with one of craftsman from Enlain surfboards.

http://www.reverse-magazine.com/2016/08/enlain-made-of-wood/

I like this quote,

The surf scene in Switzerland, although there is no sea around, is a growing one.

This is what should be happening on recreational surfer owned land, next to the recreational surfer owned wooden surfboard workshop building , next to the recreational surfer funded Webber wave pool (an inclusive reality, the opposite of Kellys exclusive corporate reality) , which is a surfboard design testing laboratory, next to the surfer owned solar farm, next to the wave tank where everyones surfing reef designs are tested and evolved - the new science of wave shaping a collaborative science, next to the factory where concrete tetrapods are made for man made surfing reefs, next to the glass recycling factory (recycled glass to replace blue metal aggregate in concrete ?).

A surfing temple dedicated to surfing evolution.

that was unreal watching how to build a wooden surfboard